EDU

Enterprise

PNX Labs

PNX Labs stands as a global tech leader, focusing on crafting industrial and scientific simulations via XR technologies such as Virtual, Augmented, and Mixed Reality. Leveraging our profound expertise in science and engineering, we produce unparalleled XR solutions for diverse applications, from industrial training and CAD design to manufacturing enhancement, industrial assessments, college STEM education, and advanced education.

EDU Approved

Education Approved developers have worked side-by-side with respected educational institutions. This badge promises that you’re dealing with a trusted expert in the field.

Enterprise Approved

Enterprise Approved developers excel in delivering scalable results, backed by a successful track record with Global 2000 companies. Large enterprises trust this badge to find top-notch experts.

Notable Customers:

Demo Available on ArborXR

Fluid Mechanics

Device Compatibility: Meta Quest, PICO

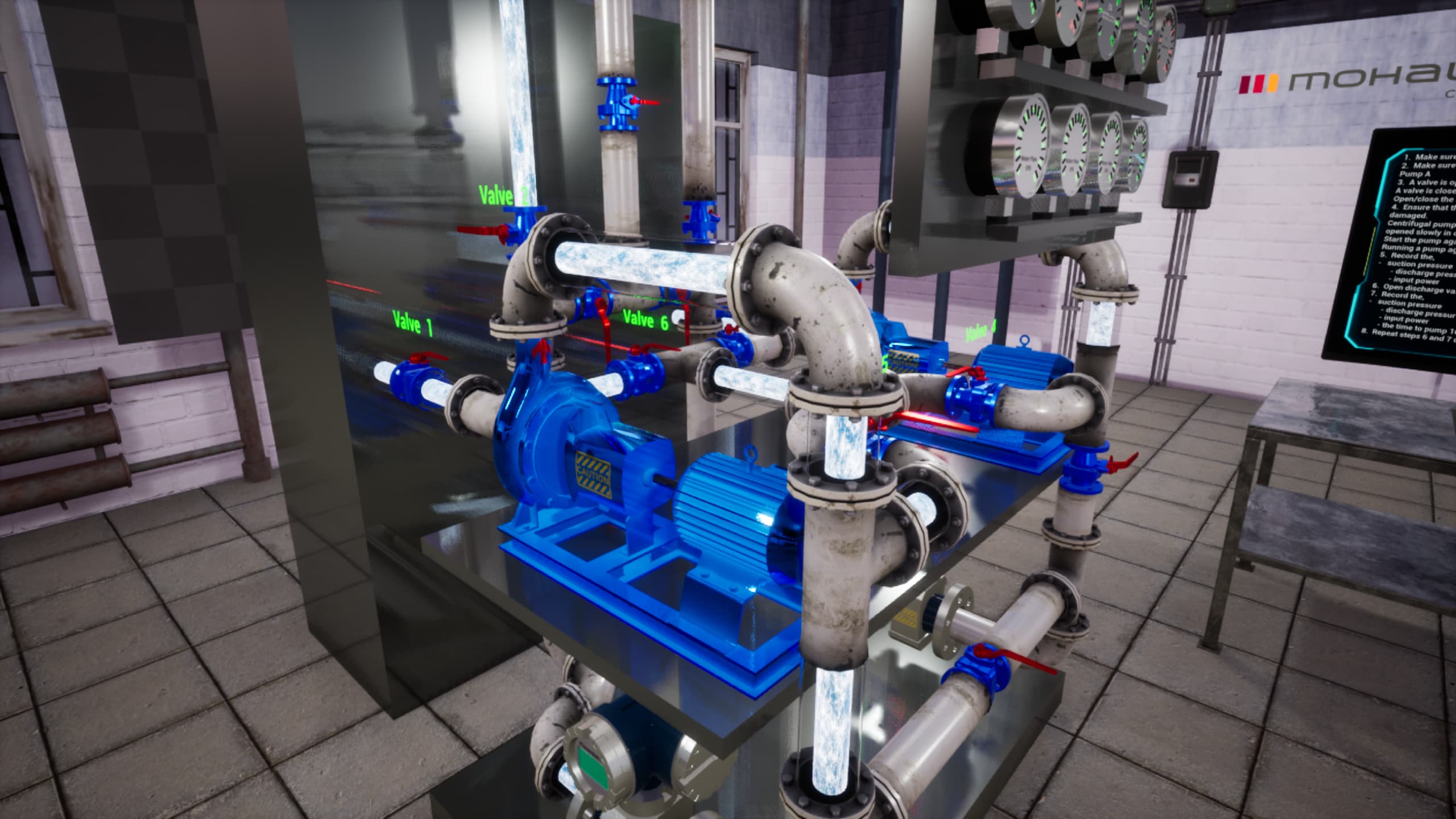

Navigating the complex world of fluid mechanics is now more engaging and educational with the introduction of a cutting-edge Virtual Reality (VR) Lab. This sophisticated and immersive platform propels learning beyond the limits of traditional classroom boundaries, offering students a hands-on, interactive experience in conducting critical experiments in fluid mechanics, including those involving centrifugal pumps, orifice calibration, and pressure loss in pipes.

Immersive Learning Environment:

The VR Lab in fluid mechanics is an expertly designed virtual environment that mirrors real-world laboratory settings. Students, equipped with VR headsets and controllers, enter a world where they can interact with realistic laboratory equipment, perform experiments, and analyze results in real-time, all within a safe, simulated setting.

Centrifugal Pumps Experiment:

One of the foundational experiments students engage in involves centrifugal pumps. Within the virtual space, students execute the setup, operation, and analysis of these pumps' performance. This immersive, interactive experiment helps students understand the mechanics and principles behind the operation of centrifugal pumps, providing them with insights that are crucial for careers in various engineering fields.

Orifice Calibration Experiment:

In the orifice calibration experiment, students utilize the VR Lab's advanced tools to measure fluid flow through different orifice types. The lab offers simulations with various flow rates and orifice diameters, allowing students to collect and analyze data, understand the relationships between different variables, and calibrate orifice meters effectively.

Exploring Pressure Loss in Pipes:

The experiment on pressure loss in pipes within the VR Lab is a comprehensive exploration of the factors affecting fluid flow and pressure in piping systems. The virtual environment provides various pipe types, sizes, and configurations, enabling students to conduct experiments to understand pressure loss dynamics in intricate detail.

Get the Free Demo Now

Install this free demo on?your XR devices in minutes with ArborXR.

Metal 3D Printer

Device Compatibility: Meta Quest

Entering the Virtual Space:

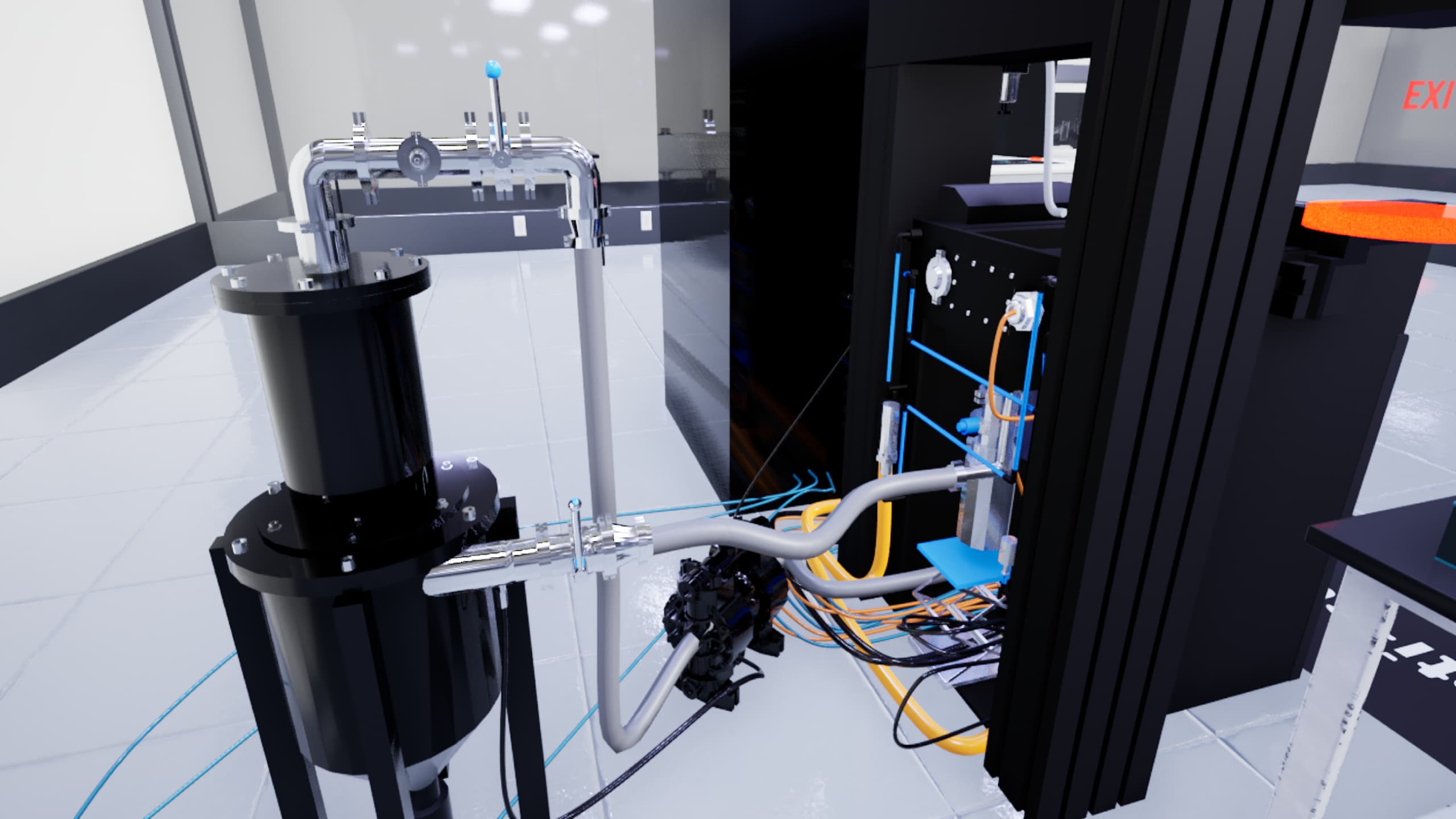

Upon entering the VR Lab, students are greeted by a simulated, fully-equipped, and safe virtual laboratory environment, mirroring the real-world settings of advanced 3D printing facilities. With a high-definition VR headset and controllers, students navigate through the virtual lab, interacting with the Aconity 3D printer, tools, and materials, gaining practical experience akin to a physical lab setting.

Learning to Operate the Aconity 3D Printer:

The primary module focuses on in-depth training on operating the Aconity 3D Printer. Students engage in every aspect of the 3D printing process: from machine preparation and configuration to the final printing stage. Guided tutorials and interactive simulations lead them through setting up the printer, selecting and loading micronized metal powders, and configuring print settings. This comprehensive, hands-on experience is amplified by real-time feedback and assistance, ensuring a robust learning and understanding of the machine operations.

Understanding the Materials:

A dedicated section within the VR Lab educates students about the micronized metals used in 3D printing. It highlights the properties, potentials, and the inherent risks and safety considerations of handling micronized metal powders. The interactive modules and simulations provide essential knowledge and training to handle these materials safely and effectively.

3D Model Printing and Analysis:

Students take on practical projects within the VR Lab, creating various 3D models. They are guided through the entire process: from designing and selecting appropriate materials and settings to the actual printing process. This real-time, hands-on approach ensures students gain vital practical experience, readying them for real-world applications.

Safety Training:

Safety is paramount in the VR Lab experience. A comprehensive safety module educates students on the potential risks and the necessary precautions and protocols when dealing with 3D metal printing and micronized metals. Virtual simulations provide scenarios and situations where students learn to manage and mitigate risks, ensuring their safety and the safe operation of the Aconity 3D printer.

Get the Free Demo Now

Install this free demo on?your XR devices in minutes with ArborXR.

Ion Chromatography

Device Compatibility: Meta Quest, PICO

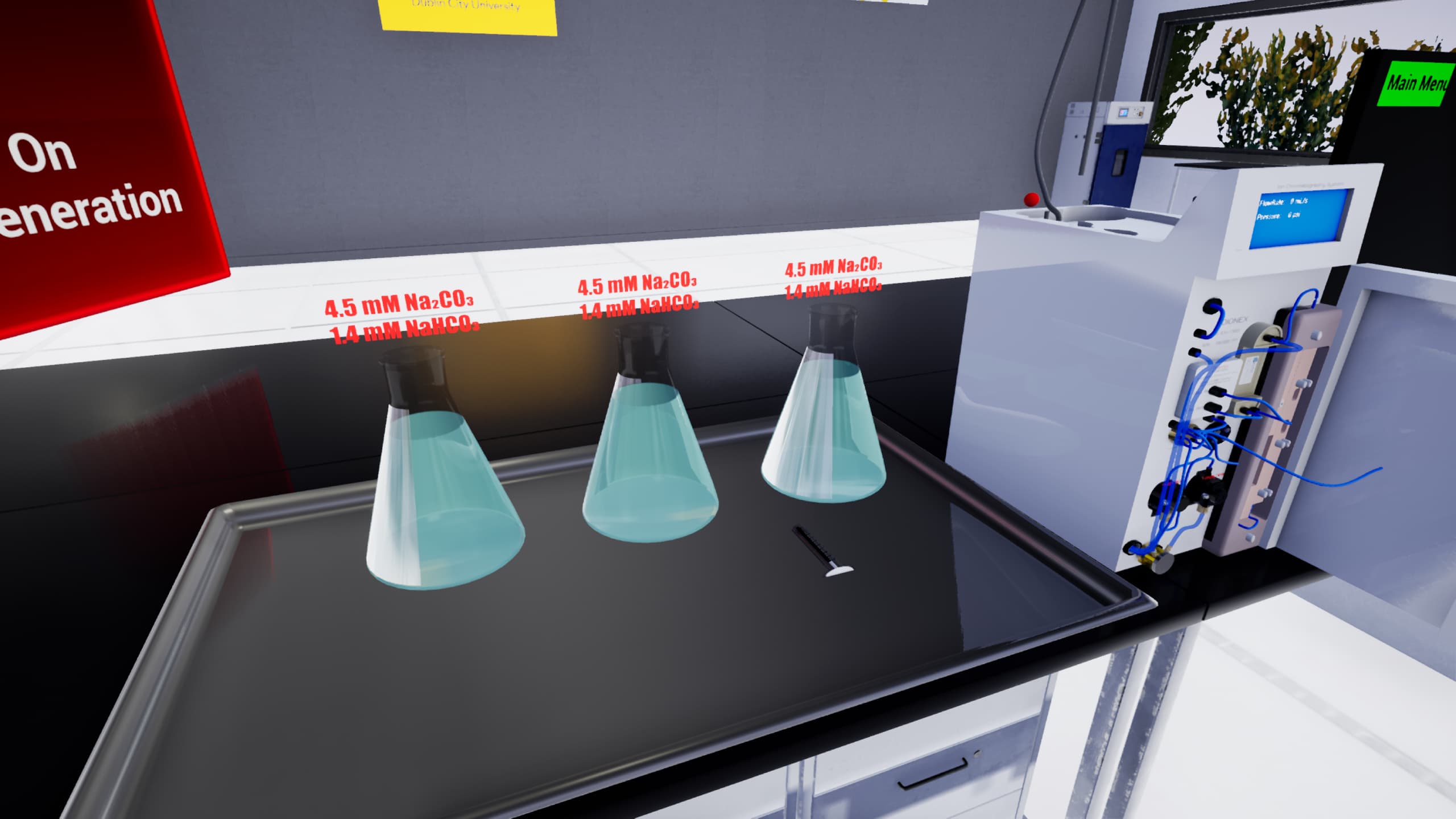

In the revolutionary Virtual Reality (VR) Lab, students embark on an immersive learning journey to master the operation of the Dionex ICx1500 for ion chromatography, a critical instrument for analyzing ion concentrations in various solutions. The VR Lab is an expansive, state-of-the-art virtual environment designed to facilitate the most comprehensive, hands-on learning experience, while eradicating the geographical and physical limitations of traditional laboratories. The engaging virtual world propels education into a new era, providing an invaluable and accessible resource for students worldwide to gain practical insights and skills related to ion chromatography.

The first phase of the VR Lab involves a detailed, step-by-step tutorial on operating the Dionex ICx1500. Through the virtual interface, students engage in realistic tasks such as calibrating the instrument, preparing samples, and managing the software controls. Each operation is guided by real-time, automated feedback, ensuring that students thoroughly comprehend each step before progressing. Beyond merely watching demonstrations, students actively participate in every process, solidifying their knowledge and boosting confidence in equipment handling.

The VR Lab further enhances learning by allowing students to virtually visualize the chromatogram of different solutions. The visualizations provide a clear, detailed, and dynamic representation of ion separation, allowing students to analyze results with unprecedented clarity and depth. This aspect of the VR Lab is invaluable for developing a robust understanding of chromatographic principles and techniques. The immersive VR environment provides an interactive, 3D visualization of the chromatogram, offering insights into the intricacies of ion separation and detection. Students can manipulate the virtual chromatograms, explore various perspectives, and engage in real-time analysis, all within the VR Lab’s controlled and supportive educational environment.

Get the Free Demo Now

Install this free demo on?your XR devices in minutes with ArborXR.

Media Gallery

Use Cases

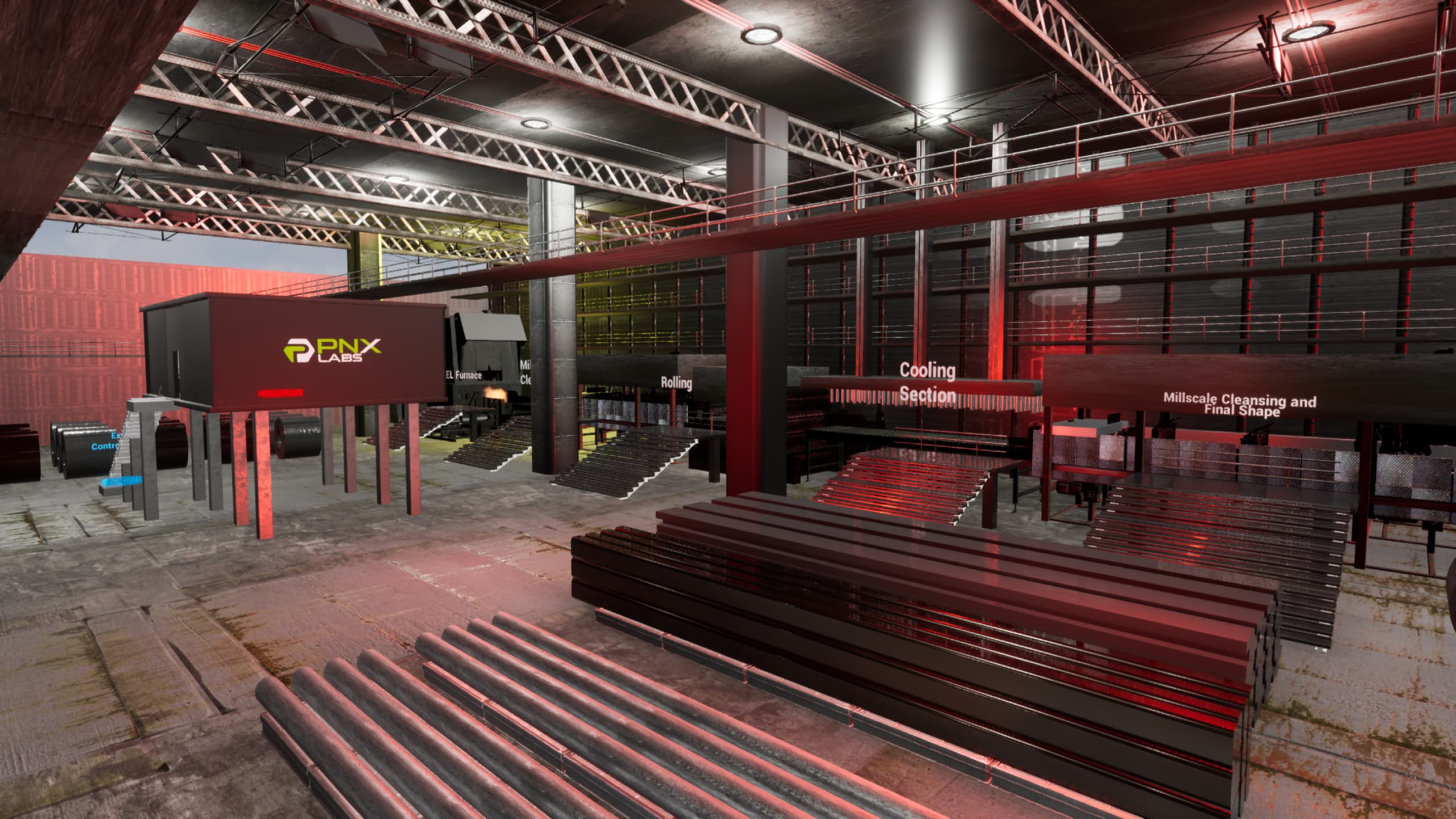

SETU Ireland’s Revolutionary Virtual Labs for Industry 4.0 Advanced Manufacturing Education

Read the Full Case Study →

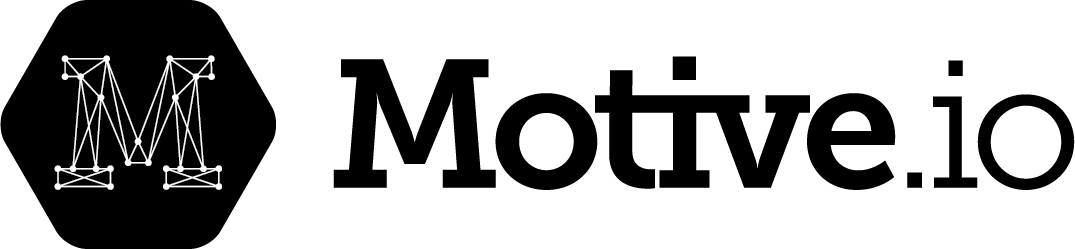

Florida International University Leaps into the Future with PNX Labs’ Virtual Labs for Mechanics of Solids and Fluid Mechanics

Read the Full Case Study →

VR Training Program for Cement Production

Read the Full Case Study →

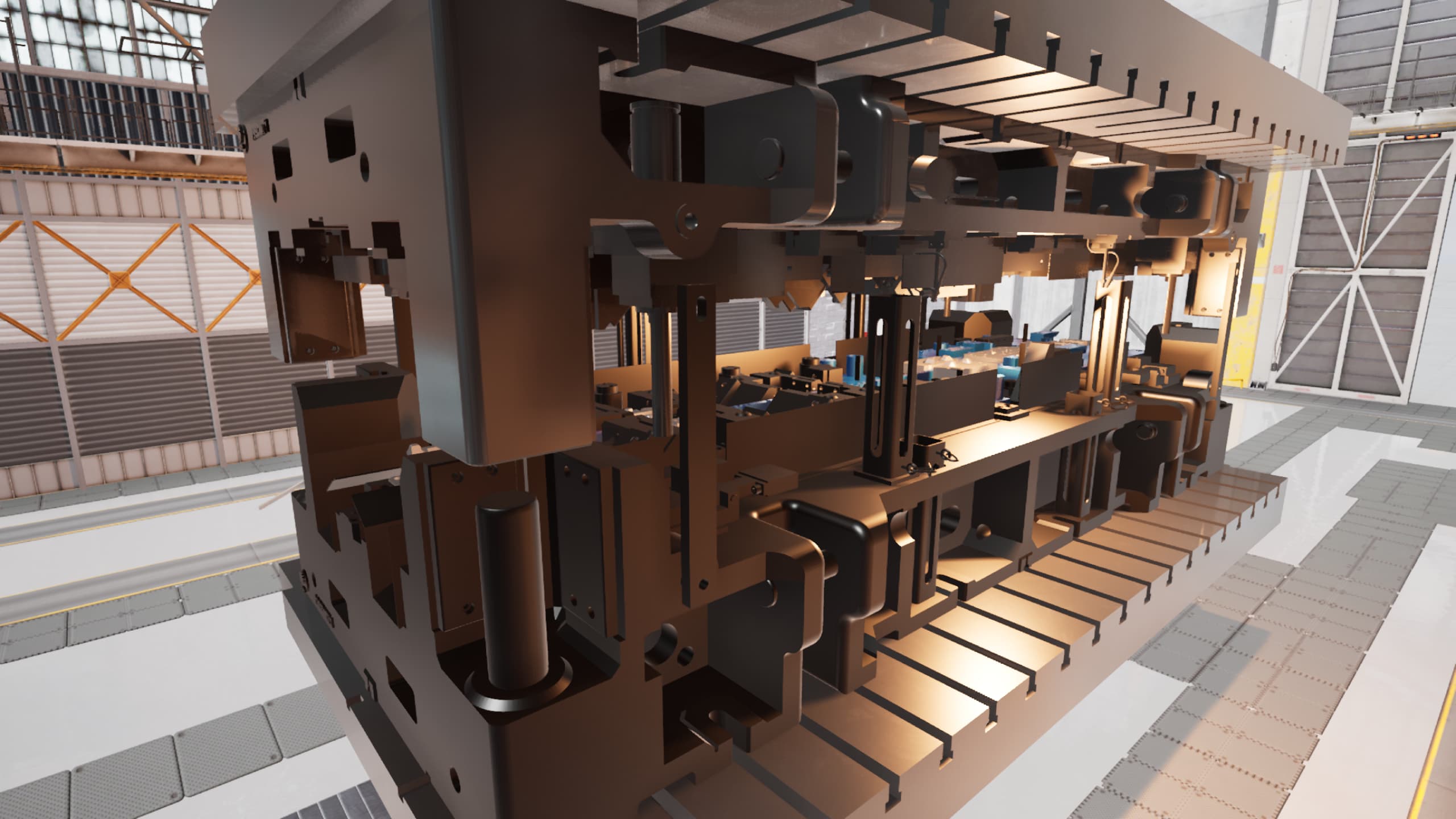

PNX Labs and Metalsa Mexico Collaborate on Groundbreaking Die Tool Scrap Simulation

Read the Full Case Study →

PNX Labs and XDM3D Ink Landmark Partnership: Merging XR Simulations with Metal 3D Printing

Read the Full Case Study →

Elevating Cement Production Training through VR Technology: The Cemex Initiative

Read the Full Case Study →

PNX Labs Breaks New Ground with VR Welding Training Developed for Prolec General Electric

Read the Full Case Study →

Testimonials

“At Florida International University, our commitment is to equip students with top-tier educational tools. PNX Labs, with their dual expertise in VR/AR and relevant subject matters, became our chosen partner for engineering virtual labs. The journey from conceptualization to execution was seamless, and the resulting quality exceeded our expectations. We’re eager to further explore PNX Labs’ innovative solutions.”

– Dr Meer Safa, Undergraduate Lab Manager and Safety Manager, Florida IU

“PNX Labs has revolutionized our approach to metal 3D printing education. With the complexity and potential hazards of the aconity 3D printer, their virtual simulations provide a groundbreaking way to instruct students safely. Their dedication to educational excellence and engineering expertise is truly commendable.”

– Dr Muhannad Ahmed Obeidi – Advanced Manufacturing Processes and Materials Science, Dublin City University

“PNX Labs offers top-tier VR simulations, proving invaluable in our industrial engineering education. The ability to educate more students concurrently and more efficiently has been transformative. It’s evident that gamified learning, as provided by PNX Labs, is reshaping the future of education.”

– Dr Francisco Tamayo Enriquez, Doctorate and Masters Professor Tecnológico de Monterrey

“Training engineers and technicians at CEMEX is both crucial and costly, with high stakes for errors. This led us to PNX Labs, renowned for their engineering and manufacturing acumen. Their innovative solution for cement production training has successfully been adopted in over 20 of our international locations. Collaborating with PNX Labs and their Virtual Reality technology has been a game-changer for us.”

– Eduardo Gonzalez – Digital Transformation Director at CEMEX

“In our pursuit of integrating cutting-edge virtual education technologies, we sought a dependable partner. PNX Labs proved to be exceptional in enhancing our mechanical engineering curriculum. Thanks to their solutions, our students learn more efficiently, with the flexibility to revisit experiments. Our collaboration with PNX Labs, especially their bespoke virtual labs, has been seamless and unparalleled.”

– Hans Moolman – AR/VR Research Fellow – MTU, Kerry

Top Product Offerings

With our platform we can develop any College Engineering lab in 2-3 days. Our team has developed over 1000 College labs ranging from Fluid Mechanics and Materials Science to Advanced Physics, Chemical equipment and Biotechnology.

Contact us so we can develop a free demo tailored to your needs so we can visualize together how you can benefit from our Virtual Labs.

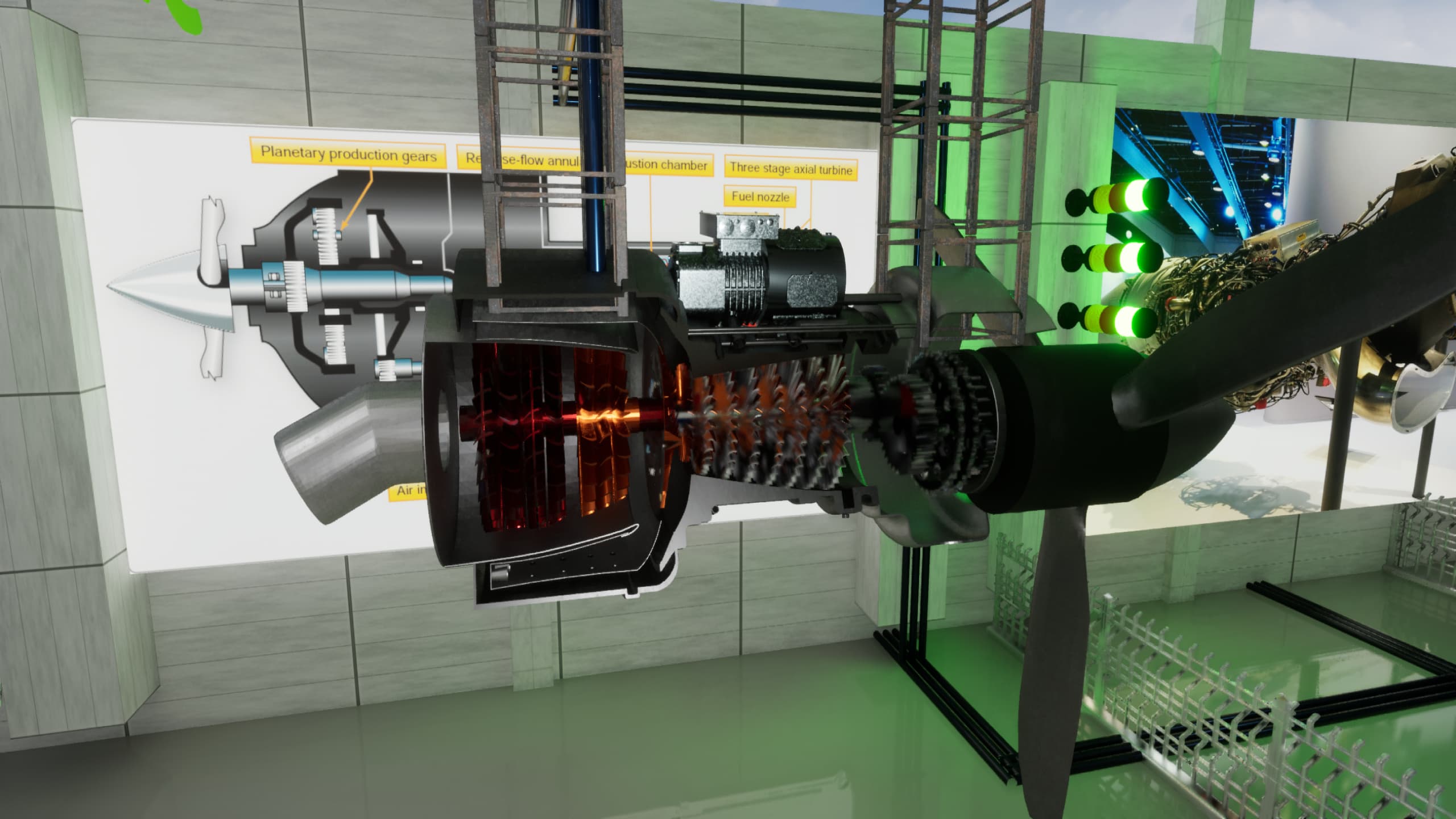

Unparallel Virtual Simulations for Mechanical Engineering. Simulations of a wide range or instruments and materials. Some of the simulations are VR and Windows simulations of Universal Test Machines, Torsion, Tensile and Compression tests, Impact, Rockwell, Brinell and Vickers tests. Euler Buckling, Poissons Ratio and Beam Bending.

Heat Exchanger, Pumps in series and parallel, pressure drop in pipes, flow measurement, combined convection and radiation, Centrifugal pumps, Drag and Lift forces, Transient Heat Transfer and More.

With our platform we can simulate any industrial setup, equipment for training and education. Our team has 20+ years experience in the manufacturing industry and with a strong background in Science and Engineering we can develop the best virtual solutions for your organization.

Contact us so we can develop a free demo tailored to your needs so we can visualize together how you can benefit from our Virtual Labs.

PNX Cad XR is a Virtual Reality inspection software that enables immersive manipulation and analysis of 3D models. This accelerates problem identification and reduces design errors, allowing for more iterations and fewer prototypes. The software offers a range of functionalities, such as dismantling pieces, sectioning, measuring, changing materials, scaling up or down, applying light sources, and adding annotations and photos. These features make it easier to interpret 3D model volume and accelerate product validation.

Additional Details

ArborXR Demo Available: Yes

Trial Period Offered: Yes

Regions Supported: North America, South America, APAC, EMEA, LATAM

Notable Milestones / Awards:

- ISO 27001

Type of Developer: AR, VR

Type of Content: Custom, Off-the-Shelf

Device Support: HTC, Oculus / Meta, PICO, Lenovo, DPVR

Industries: Automotive, EDU (Higher-Ed), EDU (K-12), Energy / Oil & Gas, Food / Sanitation, Healthcare / Medical, Manufacturing, Safety

Established: 2016

Headquarters: Germany

Access All Demos Now

Access demo apps from top enterprise and education developers for free.